When people search for “anti tarnish meaning,” they want clarity on what the term actually represents. In simple terms, anti tarnish refers to any process, material, or treatment that prevents or slows down tarnishing on metals. Tarnish is the dull, discolored film that develops on surfaces like silver, copper, and brass when they react with oxygen, moisture, or sulfur in the air. Anti tarnish methods whether coatings, chemical treatments, or storage solutions act as protective shields. For jewelers, designers, and even everyday consumers, understanding anti tarnish is more than technical knowledge. It’s about preserving value, beauty, and functionality. This article explores anti tarnish in depth its science, its importance, and its applications across industries.

What is Tarnish?

Before we define anti tarnish, it’s important to understand tarnish itself. Tarnish is a surface-level corrosion caused by environmental exposure. Unlike rust, which eats away at iron, tarnish affects metals like silver or copper, leaving a dark, cloudy surface layer.

Common causes of tarnish include:

- Sulfur compounds (from air pollution or rubber storage materials)

- Moisture (humid environments accelerate discoloration)

- Body oils and sweat (skin contact leaves residues that react with metal)

- Chemicals (lotions, perfumes, or cleaning products often speed tarnishing)

While tarnish rarely destroys the underlying material, it diminishes appearance and usability. For jewelry lovers, it means losing the luster of silver earrings. For industries, it can mean degraded electronic contacts.

The Meaning of Anti Tarnish

Anti tarnish is simply the preventive approach against tarnishing. It can take several forms:

- Physical Barriers – Applying protective coatings like lacquers, nanofilms, or plating that block exposure to air.

- Chemical Inhibitors – Using agents that bond with metal surfaces and prevent oxidation.

- Environmental Control – Storing items in low-humidity, sulfur-free environments.

- Material Engineering – Alloying metals with elements less prone to tarnish.

Anti tarnish does not mean tarnish-proof forever. Instead, it slows the natural chemical process, often extending the shine of metals by years.

Tarnish vs. Anti Tarnish

| Aspect | Tarnish | Anti Tarnish |

|---|---|---|

| Definition | Discoloration of metals due to reaction | Methods to prevent or slow that discoloration |

| Cause | Oxygen, sulfur, moisture, body oils | Protective coatings, inhibitors, environment |

| Result | Dark, dull, less attractive surface | Shiny, bright, protected surface |

| Common Metals Affected | Silver, copper, brass | All protected by coatings or treatment |

Why Anti Tarnish Matters

Anti tarnish methods matter because metals are central to both everyday and luxury life. Jewelry, coins, electronics, cutlery, and decorative art all depend on appearance and functionality. Tarnished metals may still function, but they lose commercial and emotional value.

For example:

- Silver Jewelry – Consumers expect brilliance, not dull gray.

- Electronics – Tarnish on contacts can disrupt conductivity.

- Tableware – Heirloom cutlery is prized for shine.

- Industrial Parts – Corrosion may reduce safety.

Without anti tarnish methods, maintenance becomes expensive and time-consuming.

The Science of Anti Tarnish

Tarnish is fundamentally a redox reaction: metals react with oxygen and sulfur to form sulfides or oxides. Anti tarnish works by interrupting this chain.

- Barrier coatings block oxygen or sulfur molecules.

- Chemical bonds (like thiols) occupy surface sites, preventing reactions.

- Controlled storage reduces the number of reactive molecules available.

This blend of chemistry and engineering shows why anti tarnish is both science and art.

Common Anti Tarnish Methods and Effectiveness

| Method | How It Works | Typical Longevity | Common Use Cases |

|---|---|---|---|

| Lacquer coating | Transparent film blocks air | 6–24 months | Jewelry, coins, cutlery |

| Nanofilm protection | Molecular-level barriers | 2–5 years | Electronics, luxury metals |

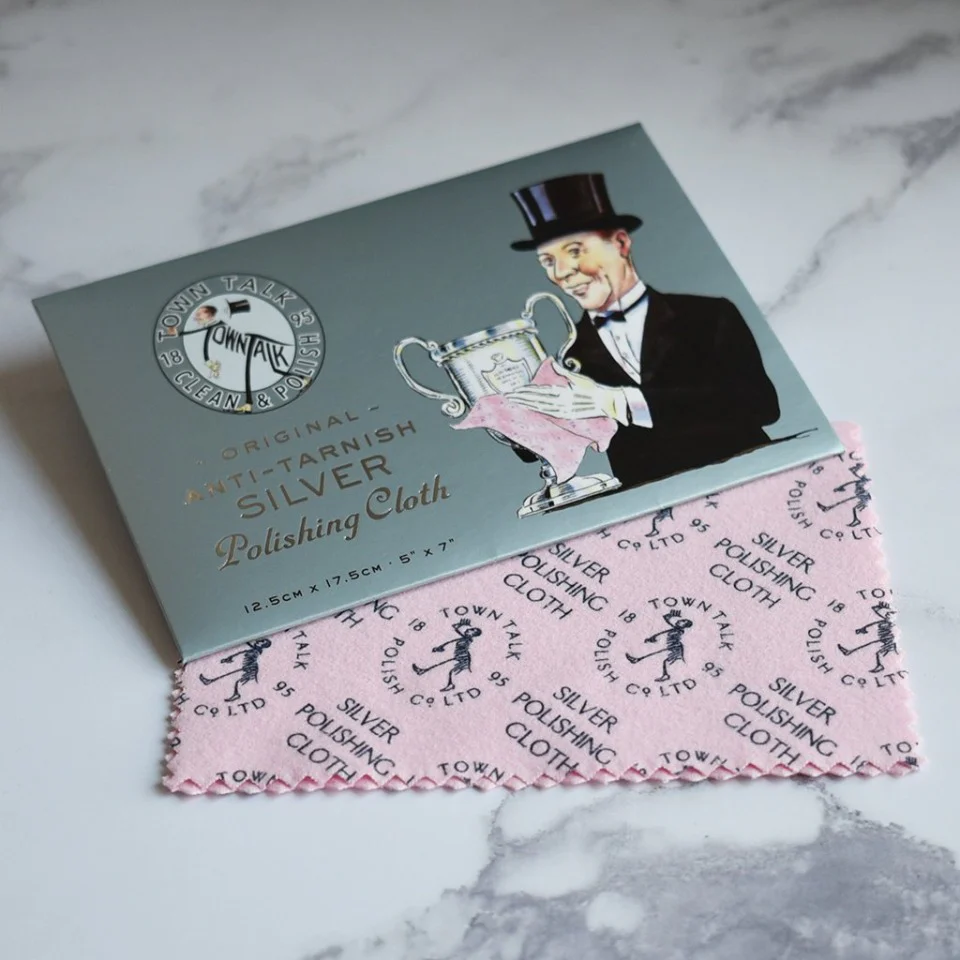

| Anti tarnish cloth/bags | Absorb sulfur and moisture | Varies | Jewelry storage |

| Alloying (e.g. sterling) | Mixes metals to resist tarnish | Permanent | Jewelry, industrial parts |

| Chemical dips | Remove tarnish + apply inhibitors | Weeks–months | Household cleaning |

Anti Tarnish in Jewelry

Jewelry is the most visible context for anti tarnish practices. Silver, in particular, is highly prone to discoloration. Jewelers apply rhodium plating, anti tarnish lacquers, or sell anti tarnish pouches to maintain customer satisfaction. For consumers, this means longer enjoyment of items like engagement rings, necklaces, and heirloom pieces. It also means less frequent polishing, which can wear down fine details.

Anti Tarnish in Electronics

While jewelry tarnish is about beauty, in electronics it is about function. Tarnish on copper connectors or silver-plated contacts interferes with current flow. Even a thin layer of sulfide can reduce performance in smartphones, computers, or industrial equipment. Anti tarnish solutions in this field often use nanofilms or engineered alloys that combine conductivity with resistance. The stakes are higher here failure can mean system breakdown.

Anti Tarnish in Everyday Life

Anti tarnish measures aren’t only for luxury items. They exist in simple household objects too:

- Flatware and kitchen tools often come pre-coated.

- Coins are preserved in anti tarnish sleeves.

- Mirrors and decorative frames rely on protective lacquers.

Everyday exposure to oxygen means that anti tarnish silently shapes the durability of items around us.

Environmental Considerations

An important modern twist is sustainability. Traditional anti tarnish coatings often used chemicals that were toxic or non-biodegradable. Today’s focus has shifted toward eco-friendly nanotechnology thin films that provide longer protection with minimal environmental cost. This shift ensures that preservation doesn’t come at the cost of planetary health.

Eco-Friendly vs. Traditional Anti Tarnish Approaches

| Aspect | Traditional Methods | Eco-Friendly Methods |

|---|---|---|

| Chemicals Used | Heavy lacquers, solvents | Water-based coatings, nanofilms |

| Environmental Impact | Often toxic, hard to dispose | Minimal, biodegradable |

| Longevity | Moderate | Longer-lasting |

| Modern Adoption | Declining | Increasing |

Psychological Value of Anti Tarnish

Beyond utility, anti tarnish has a psychological component. People associate shiny metal with purity, luxury, and value. A tarnished ring can feel “dirty” or “cheap,” even if the underlying material is pure. Anti tarnish therefore sustains not only the material worth of items but also their emotional resonance.

Risks and Misunderstandings

Anti tarnish isn’t infallible. Misconceptions include:

- “It lasts forever.” In reality, coatings wear away.

- “All anti tarnish is the same.” Effectiveness varies widely.

- “Cleaning equals prevention.” Polishing removes tarnish but does not prevent it.

These nuances matter for both consumers and industries.

Common Misconceptions About Anti Tarnish

| Misconception | Reality |

|---|---|

| Anti tarnish is permanent | It slows tarnish but rarely eliminates it |

| All coatings are equal | Quality differs by method and application |

| Cleaning provides protection | Cleaning restores shine but does not protect |

| Tarnish damages the metal itself | Tarnish is surface-level, reversible |

Anti Tarnish in Cultural Context

Across cultures, shiny metals symbolize wealth and beauty. Gold crowns, silver cutlery, or copper artifacts are all meant to be seen in brilliance. Ancient civilizations even experimented with natural coatings oils, resins, or waxes as anti tarnish methods. Today’s anti tarnish is thus part of a long human tradition of preserving shine as a form of value.

Future of Anti Tarnish

Looking ahead, nanotechnology and smart materials will dominate. Imagine jewelry that signals when a coating is wearing off, or electronics with self-repairing anti tarnish films.The field is shifting from passive protection to active intelligence, ensuring metals remain both functional and beautiful for longer.

Conclusion

The meaning of anti tarnish extends far beyond a technical definition. It is the science and practice of preserving metals against natural decay, whether in jewelry, electronics, or household goods. At its heart, anti tarnish reflects human desire: to maintain beauty, value, and function in the things we create and cherish. By understanding anti tarnish methods, consumers and industries alike can make smarter decisions choosing solutions that are effective, sustainable, and aligned with the way we live today.

FAQs

1. What does anti tarnish actually mean?

Anti tarnish refers to methods or treatments designed to prevent or slow the dulling or discoloration of metals caused by oxidation, sulfur, or environmental exposure.

2. Is anti tarnish permanent?

No, anti tarnish solutions are not permanent. They can extend the shine of metals for months or years, but most coatings and treatments eventually wear off.

3. Which metals benefit most from anti tarnish treatments?

Metals such as silver, copper, and brass benefit the most since they are highly prone to tarnishing. Even gold alloys and electronic components often use anti tarnish protection.

4. How can I protect my jewelry from tarnishing at home?

Store jewelry in anti tarnish cloths or bags, avoid exposure to chemicals, and use protective coatings or dips as recommended.

5. Are modern anti tarnish methods eco-friendly?

Yes, many newer approaches use water-based coatings, nanotechnology, and biodegradable materials, which are safer for both users and the environment.